Precision Automatics: Revolutionizing Modern Manufacturing

Table of Contents

Precision automatics are transforming the way industries operate, offering unparalleled accuracy and efficiency in manufacturing processes. These advanced systems are designed to execute tasks with minimal human intervention, ensuring consistent quality and optimal performance. In today’s competitive market, precision automatics have become a cornerstone of innovation, enabling businesses to meet the growing demands for precision-engineered products.

As industries evolve, the need for precision automatics has grown exponentially. From automotive to aerospace, these systems are redefining production standards and setting new benchmarks for excellence. The keyword "precision automatics" encapsulates the essence of modern manufacturing, where precision, automation, and technology converge to create solutions that drive progress.

Read also:Understanding The Zodiac Year 1965 Insights And Meanings

In this article, we will explore the world of precision automatics, delving into their types, applications, benefits, and challenges. We will also examine the future trends shaping this field and highlight real-world examples that demonstrate their impact. By the end of this article, you will have a comprehensive understanding of precision automatics and their significance in today’s industrial landscape.

What Are Precision Automatics?

Precision automatics refer to advanced systems and machines that perform tasks with a high degree of accuracy and minimal human intervention. These systems are designed to automate complex processes, ensuring consistent quality and efficiency. The term "precision automatics" encompasses a wide range of technologies, including CNC machines, robotic arms, and automated assembly lines.

At the core of precision automatics is the integration of cutting-edge technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT). These technologies enable machines to analyze data, make decisions, and execute tasks with precision. For example, CNC machines use computerized controls to cut, shape, and finish materials with micron-level accuracy, making them indispensable in industries like aerospace and medical device manufacturing.

One of the defining characteristics of precision automatics is their ability to reduce human error. By automating repetitive and complex tasks, these systems ensure that products meet exact specifications every time. This level of precision is critical in industries where even the slightest deviation can lead to costly errors or safety hazards. As a result, precision automatics have become a key component of modern manufacturing processes.

Types of Precision Automatics

Precision automatics come in various forms, each designed to address specific needs and applications. Below are some of the most common types:

CNC Machines

CNC (Computer Numerical Control) machines are widely used in industries that require high precision, such as aerospace, automotive, and electronics. These machines use pre-programmed software to control the movement of tools and machinery, enabling them to perform tasks like cutting, drilling, and milling with exceptional accuracy.

Read also:Razor Haircuts For Medium Length Hair The Ultimate Guide To Stylish And Modern Looks

Robotic Arms

Robotic arms are versatile tools used in assembly lines and manufacturing plants. Equipped with sensors and actuators, these arms can perform tasks such as welding, painting, and material handling with precision. They are particularly useful in environments where human intervention is dangerous or impractical.

Automated Assembly Lines

Automated assembly lines integrate multiple precision automatics systems to streamline production processes. These lines are designed to handle tasks such as component assembly, quality inspection, and packaging, ensuring that products are manufactured efficiently and consistently.

Applications in Industries

Precision automatics have found applications in a wide range of industries, each benefiting from their ability to enhance accuracy and efficiency. Below are some key sectors where precision automatics are making a significant impact:

Aerospace

In the aerospace industry, precision automatics are used to manufacture components that meet stringent safety and performance standards. CNC machines and robotic arms are employed to produce parts like turbine blades, fuselage sections, and avionics systems with micron-level accuracy.

Medical Devices

The medical device industry relies heavily on precision automatics to produce instruments and implants that require exact specifications. For example, robotic systems are used to assemble microsurgical tools, while CNC machines are used to fabricate orthopedic implants.

Automotive

In the automotive sector, precision automatics play a crucial role in the production of engines, transmissions, and other critical components. Automated assembly lines ensure that vehicles are manufactured with consistent quality and meet regulatory requirements.

Benefits of Precision Automatics

The adoption of precision automatics offers numerous advantages, making them an essential tool for modern industries. Some of the key benefits include:

- Increased Efficiency: Precision automatics streamline production processes, reducing cycle times and increasing throughput.

- Enhanced Accuracy: These systems eliminate human error, ensuring that products meet exact specifications every time.

- Cost Savings: By automating repetitive tasks, businesses can reduce labor costs and minimize material waste.

- Improved Safety: Precision automatics reduce the need for human intervention in hazardous environments, enhancing workplace safety.

Challenges in Implementation

While precision automatics offer numerous benefits, their implementation is not without challenges. Some of the key obstacles include:

High Initial Costs

The upfront investment required to implement precision automatics can be significant. Businesses must carefully evaluate the costs and benefits to ensure a positive return on investment.

Technical Expertise

Operating and maintaining precision automatics systems requires specialized knowledge and skills. Companies may need to invest in training or hire experts to manage these systems effectively.

Integration with Existing Systems

Integrating precision automatics with legacy systems can be complex and time-consuming. Businesses must ensure compatibility and address potential bottlenecks during implementation.

Future Trends in Precision Automatics

The field of precision automatics is constantly evolving, driven by advancements in technology and changing market demands. Some of the key trends shaping the future of this industry include:

Artificial Intelligence and Machine Learning

AI and machine learning are enabling precision automatics systems to become more intelligent and adaptive. These technologies allow machines to analyze data, learn from experience, and optimize performance over time.

Collaborative Robots

Collaborative robots, or cobots, are designed to work alongside humans, enhancing productivity and safety. These robots are equipped with advanced sensors and algorithms to ensure seamless interaction with human operators.

Sustainability

As industries focus on sustainability, precision automatics are being developed to minimize energy consumption and reduce waste. For example, energy-efficient CNC machines and recyclable materials are becoming increasingly popular.

Key Technologies Driving Precision Automatics

Several technologies are driving the development and adoption of precision automatics. These include:

Internet of Things (IoT)

IoT enables precision automatics systems to connect and communicate with each other, creating a network of smart machines. This connectivity allows for real-time monitoring and optimization of production processes.

Advanced Sensors

Sensors play a critical role in precision automatics, providing data on variables such as temperature, pressure, and position. This data is used to ensure accurate and consistent performance.

Cloud Computing

Cloud computing provides the infrastructure needed to store and analyze large volumes of data generated by precision automatics systems. This enables businesses to gain insights and make informed decisions.

Precision Automatics in Action: Case Studies

To understand the real-world impact of precision automatics, let’s examine a few case studies:

Case Study 1: Aerospace Manufacturing

A leading aerospace company implemented CNC machines to produce turbine blades with micron-level accuracy. This resulted in a 20% increase in production efficiency and a significant reduction in material waste.

Case Study 2: Medical Device Assembly

A medical device manufacturer used robotic arms to assemble microsurgical tools. The implementation of precision automatics reduced assembly time by 30% and improved product quality.

Case Study 3: Automotive Production

An automotive company integrated automated assembly lines to produce engines. This led to a 25% reduction in production costs and improved compliance with regulatory standards.

Conclusion

Precision automatics have revolutionized modern manufacturing, offering unparalleled accuracy, efficiency, and reliability. From CNC machines to robotic arms, these systems are transforming industries and setting new standards for excellence. While challenges such as high initial costs and technical expertise remain, the benefits far outweigh the obstacles.

As technology continues to evolve, the future of precision automatics looks promising. Advancements in AI, IoT, and sustainability are driving innovation and opening new possibilities for businesses. To stay competitive, companies must embrace precision automatics and leverage their potential to drive growth and success.

We invite you to share your thoughts and experiences with precision automatics in the comments below. If you found this article informative, please share it with your network and explore our other articles for more insights into modern manufacturing technologies.

Ponyboy Curtis: Unveiling The Depth Of His Personality

How To Replace A Toilet Flapper: A Step-by-Step Guide

Hulu Programming: A Comprehensive Guide To Streaming Success

Geissele Automatics Super Precision 34mm Scope Mount

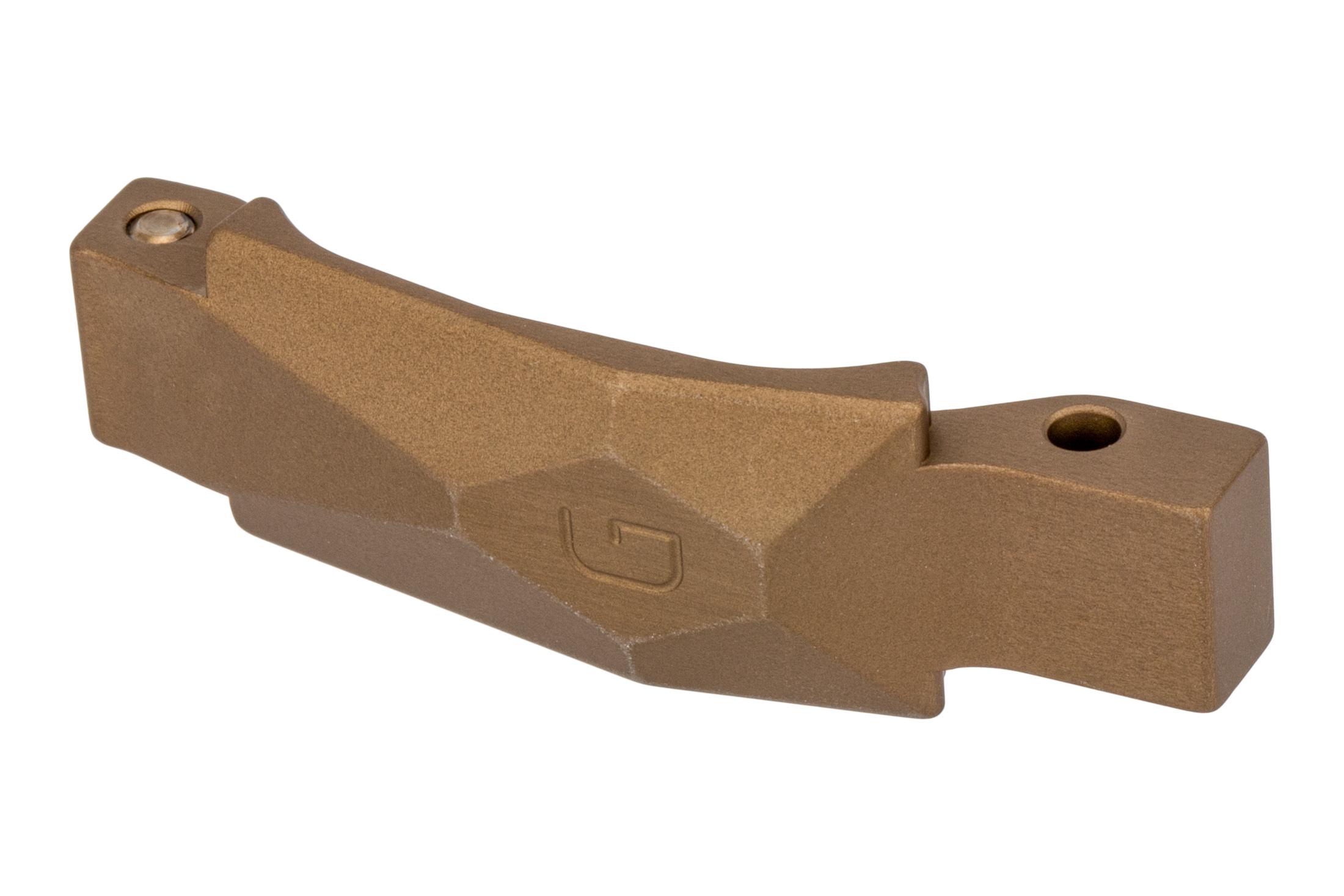

Geissele Automatics Ultra Precision 5 Axis Trigger Guard DDC 05917S